|

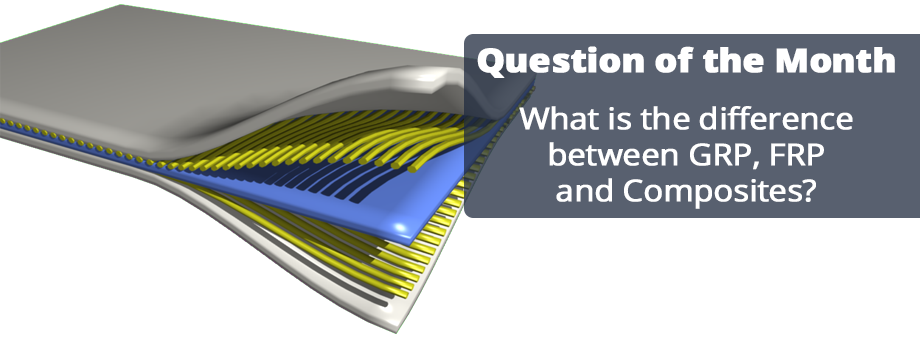

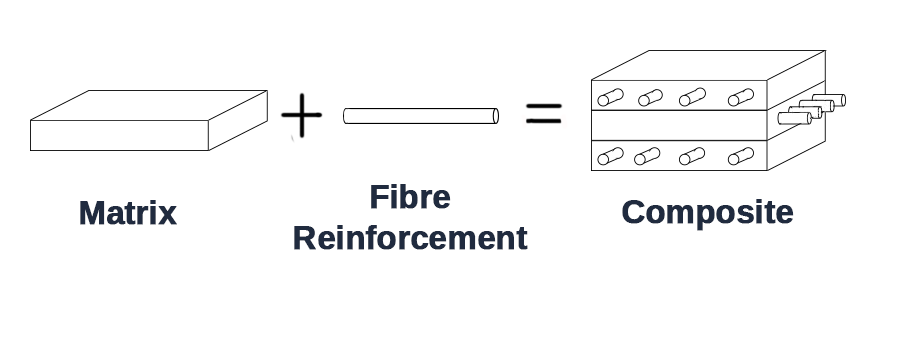

The matrix is the component of the composite that first encounters whatever forces might be imposed. The role of the reinforcement is to provide strength, rigidity and other mechanical properties to the composite.

The majority of “composites” are fibre reinforced plastics, thus the term “FRP”. The type of fibre used could be materials such as glass or carbon, and the plastic is primarily a thermosetting resin such as epoxy, polyester or vinyl ester. If glass is used for the reinforcing fibre, the composite is normally known as glass reinforced plastic, or “GRP”.

So doesn’t the term “composite” cover both GRP and FRP? Essentially, yes.

In general, the word “composites” will refer to the industry of composites. However, when talking about applications and materials, the term “composite” tends to imply the use of carbon fibre reinforcements and are associated more with large scale applications. FRP is a term more commonly used when referring to engineering materials used in industrial and construction applications.

Glass reinforced plastic (GRP) is typically used in smaller scale applications as it is much less expensive than carbon fibre, although its strength properties are only somewhat lower than its carbon fibre counterpart. Because of its cheaper cost, it is a much more viable material for numerous smaller scale applications, such as stair treads, decking and flooring. Over the past few years there has been an increase in the use of GRP as it is the ideal material for maintaining structural strength and long lasting durability.

To summarise, both FRP and GRP are types of composite, and the difference between the two is the type of fibre being used in the composite. If the fibre in the composite is glass, then it is known as GRP; if the fibre is any other type of fibre than glass, it is known as FRP.

|